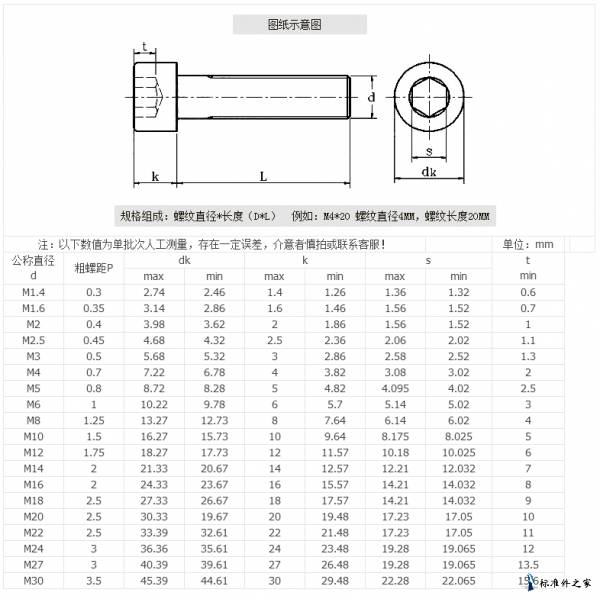

| ||||||||||

| 注:以下数值为单批次人工测量,存在一定误差,介意者慎拍或联系客服! | 单位:mm | |||||||||

| 公称直径 d | 粗螺距P | dk | k | s | t min | |||||

| max | min | max | min | max | min | |||||

| M1.4 | 0.3 | 2.74 | 2.46 | 1.4 | 1.26 | 1.36 | 1.32 | 0.6 | ||

| M1.6 | 0.35 | 3.14 | 2.86 | 1.6 | 1.46 | 1.56 | 1.52 | 0.7 | ||

| M2 | 0.4 | 3.98 | 3.62 | 2 | 1.86 | 1.56 | 1.52 | 1 | ||

| M2.5 | 0.45 | 4.68 | 4.32 | 2.5 | 2.36 | 2.06 | 2.02 | 1.1 | ||

| M3 | 0.5 | 5.68 | 5.32 | 3 | 2.86 | 2.58 | 2.52 | 1.3 | ||

| M4 | 0.7 | 7.22 | 6.78 | 4 | 3.82 | 3.08 | 3.02 | 2 | ||

| M5 | 0.8 | 8.72 | 8.28 | 5 | 4.82 | 4.095 | 4.02 | 2.5 | ||

| M6 | 1 | 10.22 | 9.78 | 6 | 5.7 | 5.14 | 5.02 | 3 | ||

| M8 | 1.25 | 13.27 | 12.73 | 8 | 7.64 | 6.14 | 6.02 | 4 | ||

| M10 | 1.5 | 16.27 | 15.73 | 10 | 9.64 | 8.175 | 8.025 | 5 | ||

| M12 | 1.75 | 18.27 | 17.73 | 12 | 11.57 | 10.18 | 10.025 | 6 | ||

| M14 | 2 | 21.33 | 20.67 | 14 | 12.57 | 12.21 | 12.032 | 7 | ||

| M16 | 2 | 24.33 | 23.67 | 16 | 15.57 | 14.21 | 14.032 | 8 | ||

| M18 | 2.5 | 27.33 | 26.67 | 18 | 17.57 | 14.21 | 14.032 | 9 | ||

| M20 | 2.5 | 30.33 | 19.67 | 20 | 19.48 | 17.23 | 17.05 | 10 | ||

| M22 | 2.5 | 33.39 | 32.61 | 22 | 21.48 | 17.23 | 17.05 | 11 | ||

| M24 | 3 | 36.36 | 35.61 | 24 | 23.48 | 19.28 | 19.065 | 12 | ||

| M27 | 3 | 40.39 | 39.61 | 27 | 26.48 | 19.28 | 19.065 | 13.5 | ||

| M30 | 3.5 | 45.39 | 44.61 | 30 | 29.48 | 22.28 | 22.065 | 15.6 | ||

| 化学成分,%,max | ||||||||||

| 组别 | C | Si | Mn | P | S | Cr | Mo | Ni | Cu | 特性 |

| 304-A2 | 0.1 | 1 | 2 | 0.05 | 0.03 | 15-20 | 8-19 | 4 | 加工硬化率适中,适于一般的冷间加工以及伸抽,冷加工性能较好,普遍用于外六角螺钉、螺母以及垫圈产品 | |

| 316-A4 | 0.08 | 1 | 2 | 0.045 | 0.03 | 16-18.5 | 2-3 | 10-15 | 1 | 加钼,耐腐蚀能力较304强,特别适用于海水及化学介质,更加的耐腐蚀性及耐孔蚀性。 |

注: 1)如镍含量低于8%,则锰的最小含量必须为5% | ||||||||||

| 机械性能 | |||||||||||

| 类别 | 组别 | 性能等级 | 螺丝直径 | 抗拉强度mpa/mm2 | 规定非比列伸长应为mpa/mm2 | 断后伸长量mpa/mm2 | |||||

| 奥氏体 | A2,A4 | 50 | ≤ 39 | 500 | 210 | 0.6d | |||||

| 70 | ≤ 24 | 700 | 450 | 0.4d | |||||||

| 80 | ≤ 24 | 800 | 600 | 0.3d | |||||||